Ruggedised TPU Jacket Distribution Cable | 2 Fibers

High tensile strength with enhanced crush resistance

Facilitates direct connector assembly and easy stripping

Excellent coiling capability for military tactical field applications

High chemical resistance against acids and alkalies

Superior mechanical and thermal stability

- Product Description

- Specification

- Product Advantage

Product Description

1. Product Overview

This specification covers ruggedized fiber optic cable assemblies and cabling systems designed for industrial applications and harsh operating environments. These products are engineered to withstand extreme temperatures, severe weather, mechanical shocks, vibrations, tensile forces, external pressure, and corrosive atmospheres—conditions far more demanding than those encountered by standard commercial fiber optic connectors and cable assemblies.

Equipped with IP67-rated connectors, the assemblies provide dust-tight and waterproof enclosure entry points, offering plug-and-play functionality across a broad range of applications.

1.1 Product Variants

• Harsh Environment LC Patch Cord

• Receptacle Connector

• Plug Connector

• Plug Type Conversion Patch Cord

• Receptacle Type Conversion Patch Cord

• Ruggedised PUR Jacket Distribution Cable (2 Fibers)

Specification

4. Design and Construction

4.1 Design Type

RT-FT8X(AL-BZ)09Z

4.2 Compliance Standards

• IEC 60794-1

• IEC 60794-3

• IEC 60793-1

• EN 50575

• 2011/65/EC (RoHS)

• (EU) No 305/2011 (CPR)

4.3 Cable Construction Details

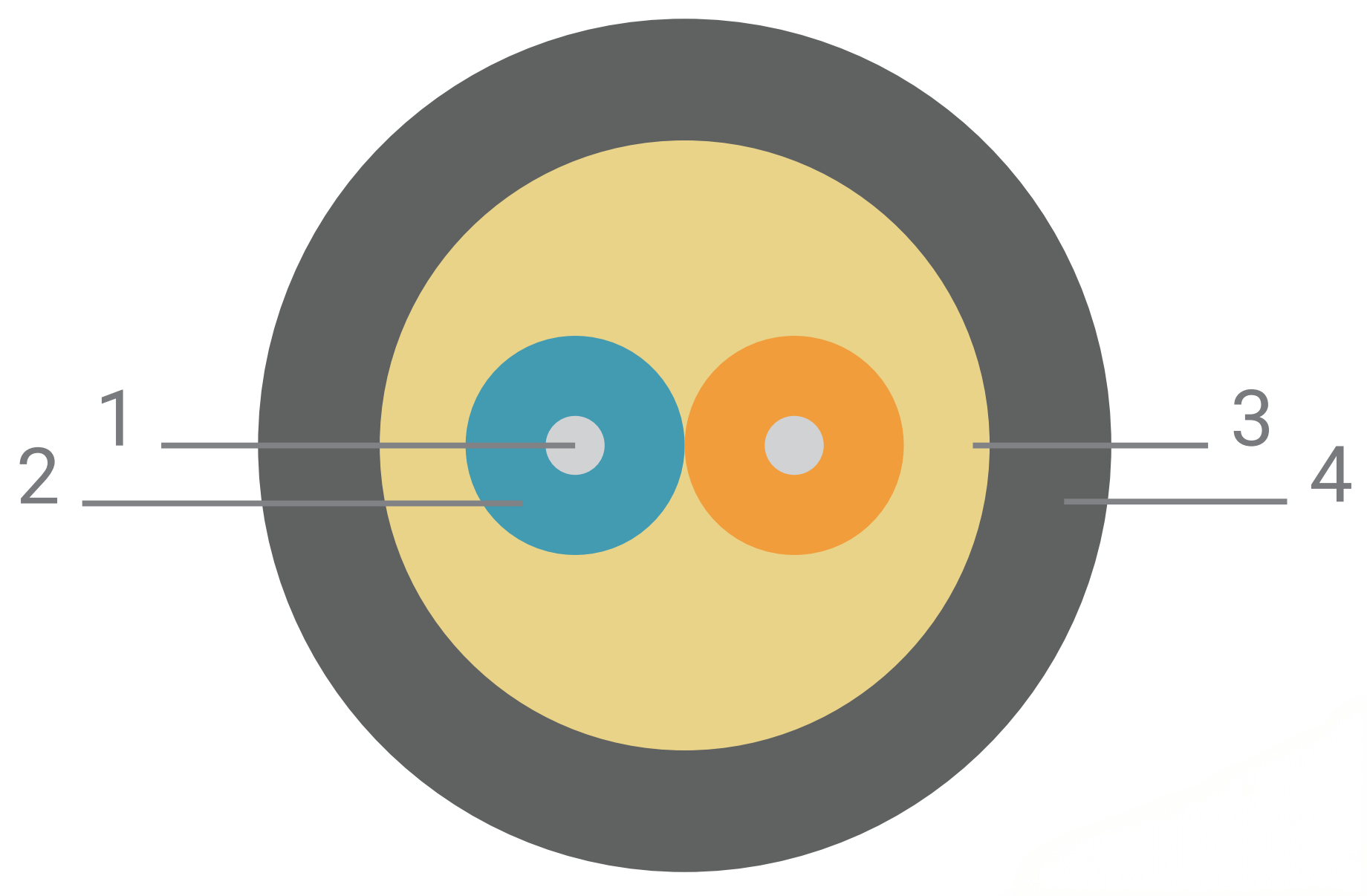

Layer Number | Component | Specification |

1 | Fiber | Single-mode or Multi-mode, 245 μm |

2 | Tight Buffer Tube | 900µ TPE |

3 | Strength Member | Water Blocking Swellable Aramid yarn |

4 | Outer Jacket | TPU |

5. Performance Specifications

Test Item | Test Standard | Specified Value |

Tensile Force | IEC 60794-1-21-E1 | 1800 N (Installation), 600 N (In Service) |

Crush Resistance | IEC 60794-1-21-E3 | 4400 N / 10 cm (Installation), 2000 N / 10 cm (In Service) |

Impact | IEC 60794-1-21-E4 | Wp=10J, R:30cm, 3 impacts |

Repeated Bending | IEC 60794-1-21-E6 | R= 20 x D, 25 cycles |

Torsion | IEC 60794-1-21-E7 | L:1 m, ±180º, 5 cycles |

Cable Bending | IEC 60794-1-21-E11A | R= 20 x D, 4 turns, 3 cycles |

5.1 Mechanical Properties

5.2 Environmental Properties

Property | Test Conditions | Test Standard | Result / Value |

Temperature Range | - | IEC 60794-1-22-F12 | -5 to +50ºC (Installation), -25 to +60 ºC (In Service), -40 to +60 ºC (Storage) |

Water Penetration | 3m specimen, 1m water depth | IEC 60794-1-2-F5B | No leakage in 24 hours |

Fire Propagation | Vertical single cable | IEC 60332-1-2 | Passed |

Smoke Density | - | IEC 61034-2 | Passed |

Halogen Acid Gas (Jacket material) | - | IEC 60754-1 | Passed |

Degree of Acidity (Jacket material) | - | IEC 60754-2 | Passed |

RoHS Compliance | - | 2011/65/EC | Compliant |

CPR Classification | - | EN 50575 | Eca |

5.3 Additional Performance Traits

• High tensile strength with enhanced crush resistance

• Facilitates direct connector assembly and easy stripping

• Excellent coiling capability for military tactical field applications

• High chemical resistance against acids and alkalies

• Superior mechanical and thermal stability

6. Ordering Information

6.1 Order Code Structure

006F-RT-FT8X(AL-BZ)09Z-6U100-1x6-XXX-XXX-Eca-1.8kN

6.2 Order Code Parameters

Order Code Element | Specification |

Fiber Count | 6 |

Sub Unit Count | 6 |

Tube Diameter (mm) nom. | 1.0 |

Cable Diameter (mm) nom. | 6.2 |

Cable Weight (kg) nom. | 32 |

6.3 Available Fiber Types

• G657.A1

• G657.A2

• G651.OM2

• G651.OM3

• G651.OM4

6.4 Sample Order Code

006F-RT-FT8X(AL-BZ)09Z-6U100-1x6-A2-GY-Eca-1.8kN

Product Advantage

-

1

Superior Environmental Adaptability: With IP67-rated connectors and a UV-stabilized TPU outer jacket, the assembly achieves excellent dustproof, waterproof, and corrosion-resistant performance. It operates stably in a wide temperature range (-25°C to +60°C in service, -40°C to +60°C in storage) and resists acid, alkali, and extreme weather, outperforming standard commercial fiber optic products.

-

2

Enhanced Mechanical Durability: Equipped with water-blocking swellable aramid yarn as the strength member, it delivers exceptional tensile (1800N for installation, 600N for service) and crush resistance (4400N/10cm for installation, 2000N/10cm for service). It also withstands impact, repeated bending, and torsion, ensuring structural integrity in high-vibration or heavy-duty scenarios.

-

3

Versatile and User-Friendly Design: Featuring a duplex LC interface, it is compatible with both single-mode (G657.A1/A2) and multi-mode (OM2/OM3/OM4) fibers. The plug-and-play functionality enables rapid deployment of temporary or permanent connectivity, while the all-dry, metal-free, and halogen-free construction simplifies on-site assembly and reduces maintenance costs.

-

4

Compliant and Safe Performance: Adheres to multiple international standards (IEC 60794-1/3, EN 50575, RoHS, CPR) and achieves Eca classification for fire safety. It emits non-corrosive fire gases, has low smoke density, and meets environmental protection requirements, making it suitable for industrial, energy, and public venue applications.

Home

Home